|

Plastic injection moulded parts Plastic injection mouldingThe plastic injection moulding process involves a plastic injection moulding machine, raw plastic material (i.e. plastic resin) and a custom mould according to the design and specification of the product required by our customers. The plastic injection moulding process is carried out by melting the plastic resin which is injected into the mould in the plastic injection moulding machine. The product is then formed when the molten plastic cools and solidifies. We have plastic injection moulding machines ranging from 25 MT to 800 MT to cater to customer orders for plastic products in different sizes. |

|

|

|

|

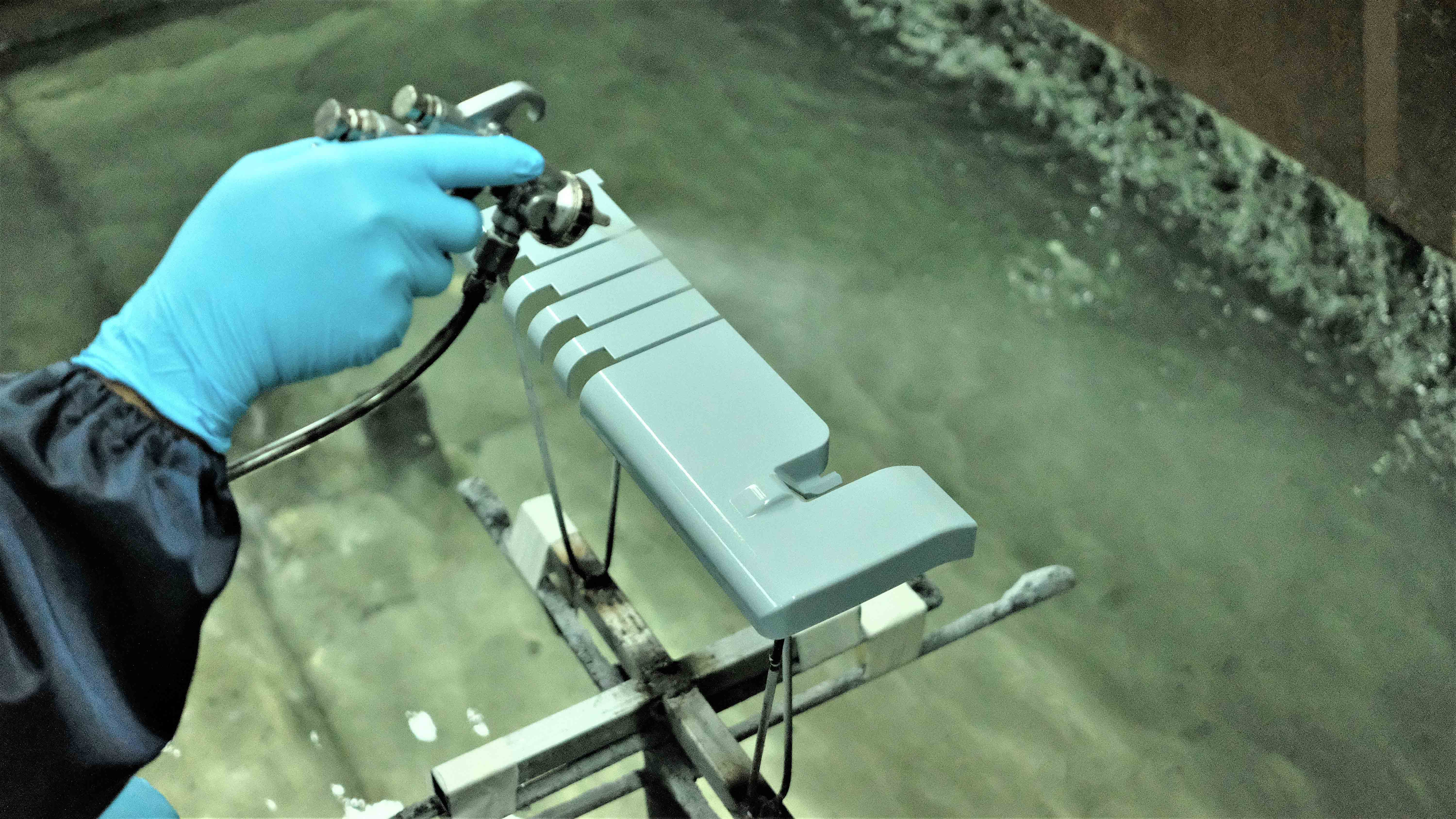

Spray coating

A process where the plastic injection moulded parts are sprayed according to the colour specified by our customers.We have a spray coating room with 2 water spray booths together with ovens

|

|

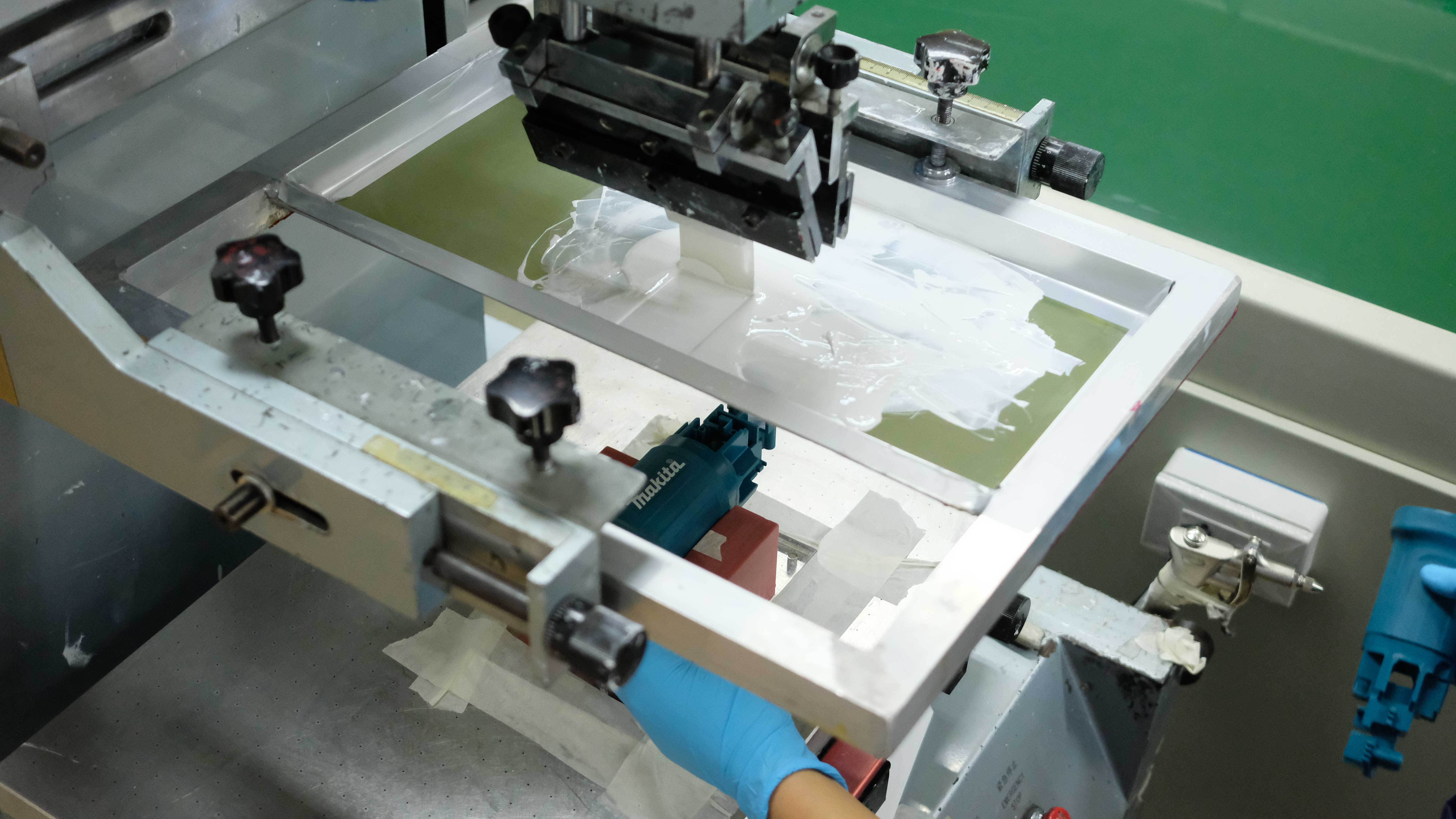

Silk Screen Printing A printing technology where a silk mesh is used to support an ink-blocking stencil. The silk mesh is stretched across a frame, usually wooden and placed on the printing surface. The frame with the silk mesh will be filled with a layer of ink and scraped across with a rubber scraper to push the ink through the permeable parts of the mesh onto the printing surface forming a sharp-edged image. We have 9 units of silk screen printing machines. |

|

|

|

|

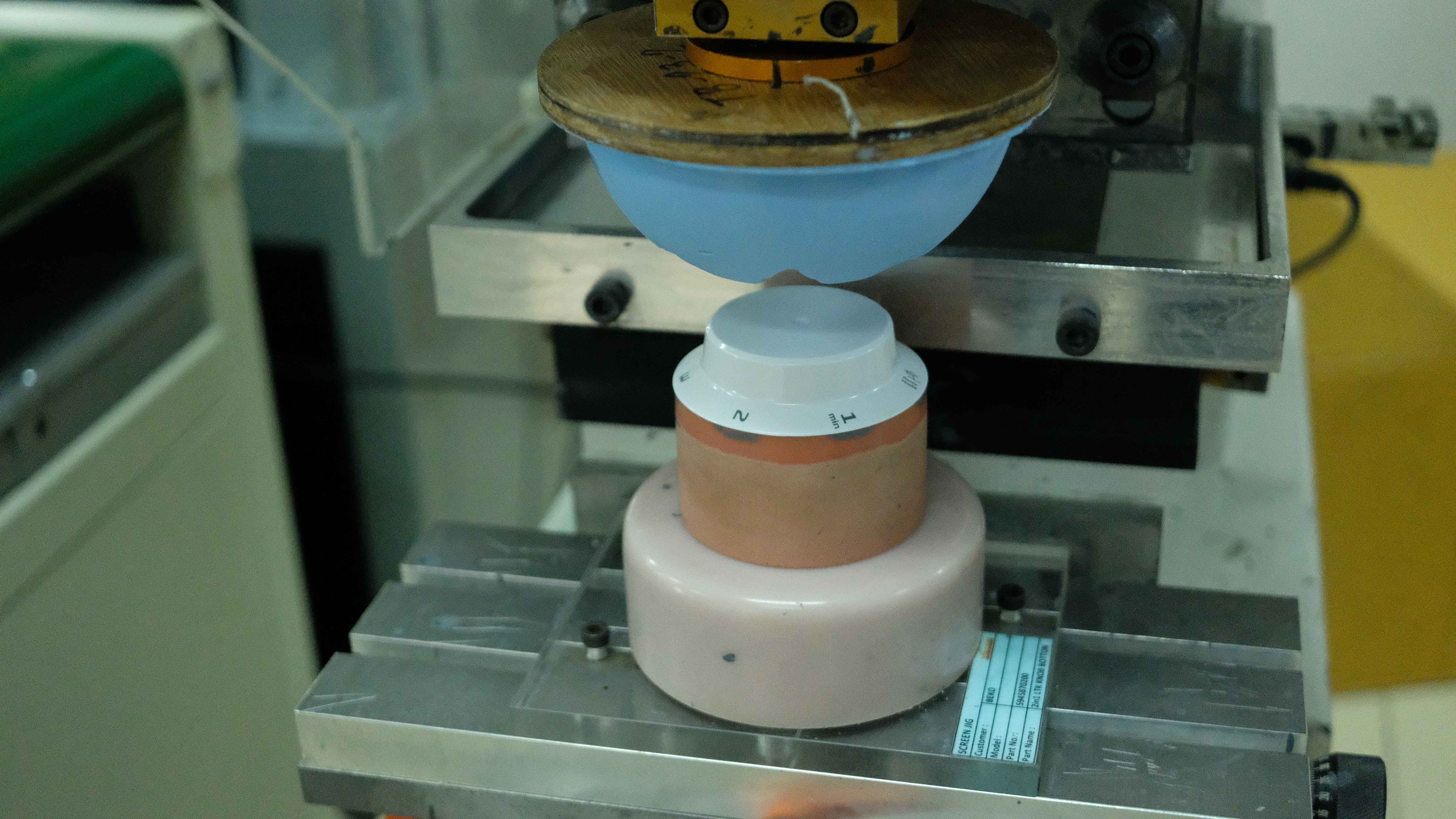

Tempo printing

A printing technology where inked image from a printing plate is transferred onto irregular or non-flat surfaces in various shapes using a flexible silicone pad. The high amount of elasticity of the flexible silicone pad enables printing to be done even on irregular or non-flat surfaces in various shapes. This enables printing to be done on various metal and non-metal materials. We have 4 tampo printing machines.

|

|

Hot stamping A dry printing method where a heated die and foil are used to apply graphic onto the surface of s sheet metal. We have 2 hot stamping machines. |

|

|

|

|

Ultra Sonic Welding Process

Branson Ultrasonic Welding machine 1 unit.

Ultrasonic welding is an industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. |

|

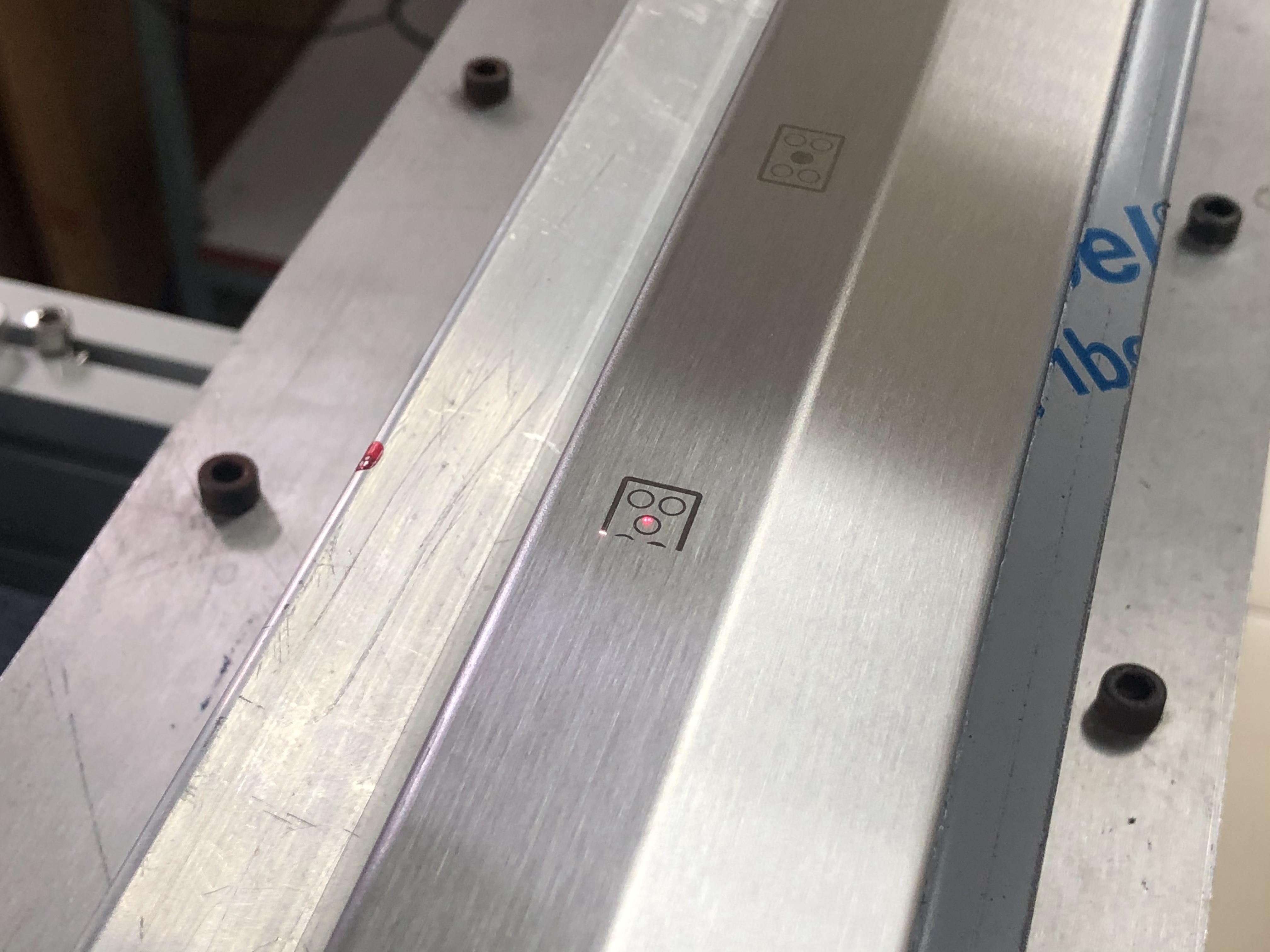

Laser Marking Process A process where a laser beam interacts with the surface of a material to slightly alter its properties or appearances. It is achieved by moving a low-powered beam slowly across the surface of a material for discolouration to achieve high-contrast marks to form the required design.We have 1 laser marking machine. which creates high-contrast marks without disrupting the material. |

|

|

|

|

Sub-assembly and assembly process

The sub-assembly process is a process to assemble all the plastic injection moulded parts to form a complete plastic injection moulded part or component. This process involves heat stacking, heat bonding or screw mounting. The assembly process is a process to assemble nameplates on the plastic injection moulded parts manufactured by us if required by our customers. |